Note

Go to the end to download the full example code

Defining a customized technology

In this example, we extend a predefined technology in IPKISS. We add a layer which is used to open the back-end oxide (top oxide) on top of the waveguides. This can be used to open a window for a sensing application, for instance to let a gas or fluid reach a ring resonator on top of which a window is opened.

This example illustrates the minimum required changes to add this layer + related settings. To build your own technology, it is recommended to start from si_fab, the demonstration PDK distributed with Luceda Academy. See also the technology guide.

Illustrates how to

create a customized technology file by importing a predefined file

add a new process layer

define import and export settings and visualization

define a virtual fabrication process

alter values in the predefined technology files

Getting started

We start by importing the si_fab technology:

import si_fab.all as pdk # noqa: F401

import ipkiss3.all as i3

from ipkiss.technology.technology import TechnologyTree

from ipkiss.process import ProcessLayer, ProcessPurposeLayer

from ipkiss.visualisation import color

from ipkiss.visualisation.display_style import DisplayStyle

from picazzo3.filters import RingRect180DropFilter

TECH = i3.TECH

TECH.name = "CUSTOMIZED TECHNOLOGY SAMPLE"

Adding a process layer

In order to add a new layer, we need to do two things:

Add the ProcessLayer - this tells ipkiss about the existence of the layer related to a specific process module

Add one or more ProcessPurposeLayers - this tells ipkiss which combinations of the new ProcessLayer and PatterPurposes exist. In this sample we’ll add only one.

TECH.PROCESS.OXIDE_OPEN = ProcessLayer(name="OX_OPEN", extension="OXO")

TECH.PPLAYER.OXO = TechnologyTree()

TECH.PPLAYER.OXO.TRENCH = ProcessPurposeLayer(

process=TECH.PROCESS.OXIDE_OPEN,

purpose=TECH.PURPOSE.DRAWING,

name="OX_OPEN",

)

Defining rules

The technology tree can contain some design rules, defaults or drawing guidelines. In this case, we’ll add a few keys for the minimum width and spacing of patterns on our new OXIDE_OPEN layer:

# define some rules

TECH.OXIDE_OPEN = TechnologyTree()

TECH.OXIDE_OPEN.MIN_WIDTH = 2.0 # minimum width of 2.0um

TECH.OXIDE_OPEN.MIN_SPACING = 1.0 # minimum spacing of 1.0um

Visualization and import/export settings

In order to make the new layer export to GDSII (and import from GDSII), we need to update the GDS LAYERTABLE.

TECH.GDSII.LAYERTABLE[(TECH.PROCESS.OXIDE_OPEN, TECH.PURPOSE.DRAWING)] = (40, 0)

In order to have ipkiss visualize the layer using the .visualize() method on a Layout view, we need to set the display style for the ProcessPurposeLayer. In this case, we set it to a yellow color with a 50% transparency.

DISPLAY_OXIDE_OPEN = DisplayStyle(color=color.COLOR_YELLOW, alpha=0.5, edgewidth=1.0)

TECH.DISPLAY.DEFAULT_DISPLAY_STYLE_SET.append((TECH.PPLAYER.OXO.TRENCH, DISPLAY_OXIDE_OPEN))

Overwriting technology keys

Overwriting technology settings which were already defined, is possible as well. We can for instance increase the default bend radius on the WG layer to 10 micrometer:

TECH.WG.overwrite_allowed.append("BEND_RADIUS")

TECH.WG.BEND_RADIUS = 10.0

Example: ring resonator with back-end opening cover layer

In order to use our newly defined technology, we make sure to import it before anything else in the main script. Make sure it is imported before ipkiss3 and before any picazzo library components ! Make sure that your new technology folder (in this case ‘mytech’) is in your PYTHONPATH.

from mytech import TECH

import ipkiss3.all as i3

from picazzo3.filters.ring import RingRect180DropFilter

We continue by defining a simple PCell which consists of a ring resonator and a cover layer:

class RingWithWindow(i3.PCell):

ring_resonator = i3.ChildCellProperty()

def _default_ring_resonator(self):

return RingRect180DropFilter()

class Layout(i3.LayoutView):

def generate(self, layout):

layout += i3.SRef(reference=self.ring_resonator, position=(0.0, 0.0))

# add a ring with the same shape as the ring resonator on the OXIDE_OPEN layer

r = self.ring_resonator

R = r.bend_radius

SHor = r.straights[0]

SVer = r.straights[1]

# generate a control shape the same shape of the ring

ring_shape = i3.Shape(

[

(-0.5 * SHor - R, 0.5 * SVer + R),

(0.5 * SHor + R, 0.5 * SVer + R),

(0.5 * SHor + R, -0.5 * SVer - R),

(-0.5 * SHor - R, -0.5 * SVer - R),

],

closed=True,

)

# use the rounding algorithm and radius of the ring to round the control shape

rounded_shape = r.rounding_algorithm(original_shape=ring_shape, radius=R)

layout += i3.Path(

layer=TECH.PPLAYER.OXO.TRENCH,

shape=rounded_shape,

line_width=TECH.OXIDE_OPEN.MIN_WIDTH,

)

return layout

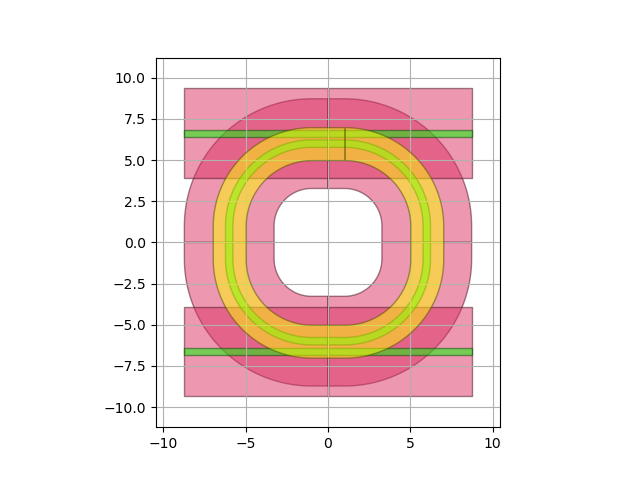

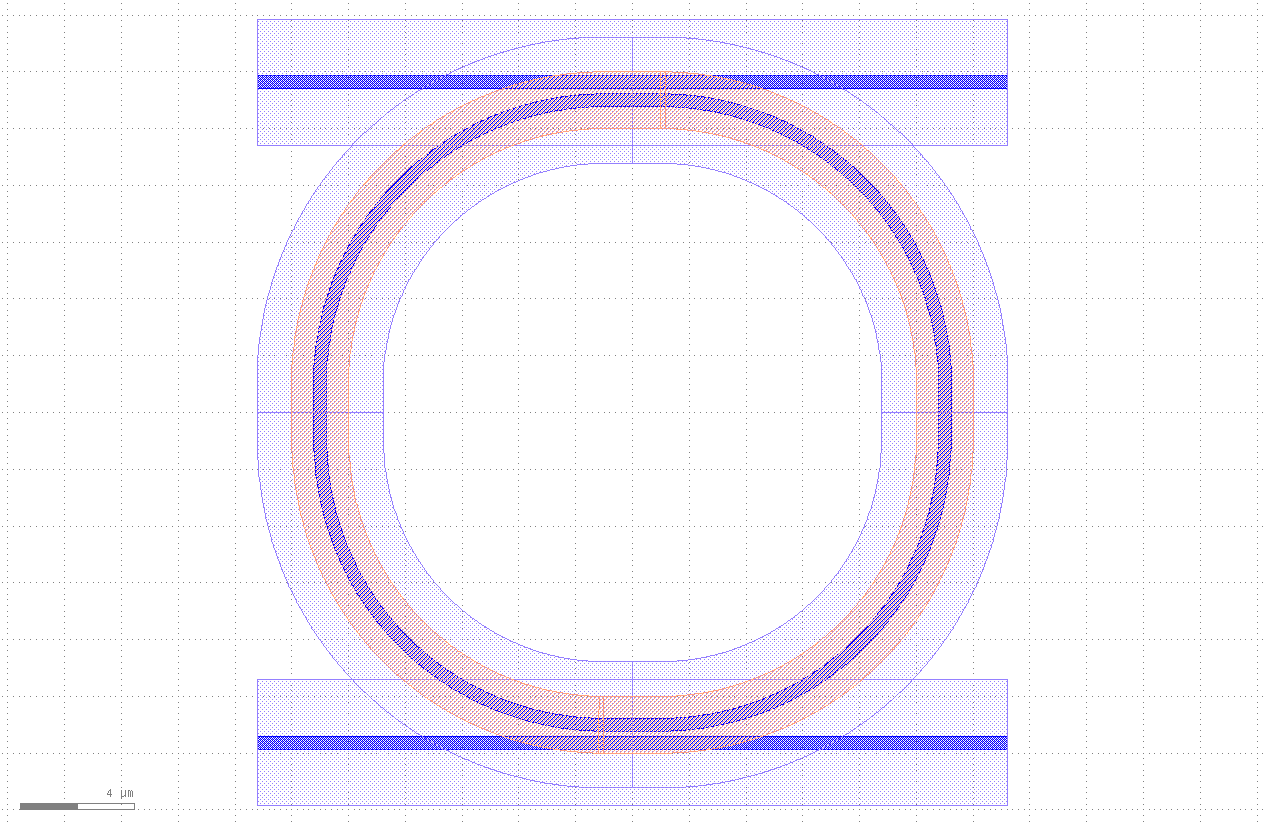

We can now instantiate the component, visualize its layout and export to GDSII:

R = RingWithWindow(name="ring_with_window")

Rlayout = R.Layout()

Rlayout.visualize() # show layout elements

Rlayout.write_gdsii("ring_with_window.gds")

Ring resonator covered by a back-end opening layer: GDSII

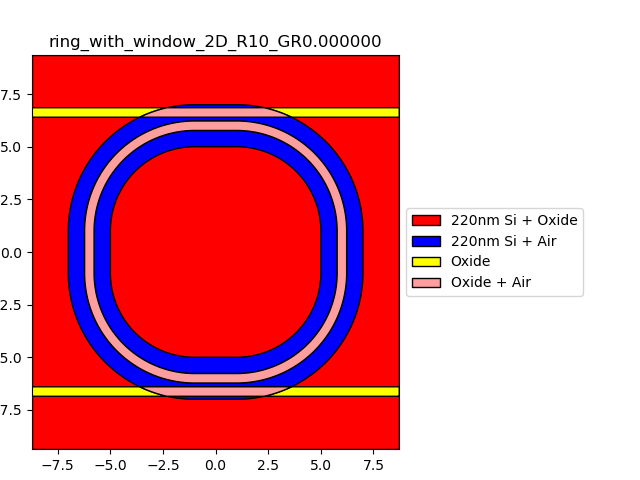

Defining the virtual fabrication

A virtual fabrication is used for:

visualizing the 2D cross-sections of the structure using

visualize_2d.top-down view of the material stacks

cross_section.exporting 3D geometries, so they can be passed to a device simulator (see also physical device simulation)

More explanation on virtual fabrication, what it does and how to set it up, can be found here.

Let’s set up the virtual fabrication now:

MSTACK_SOI_OX = i3.MaterialStack(

name="Oxide",

materials_heights=[

(TECH.MATERIALS.SILICON_OXIDE, 1.0),

(TECH.MATERIALS.SILICON_OXIDE, 0.22),

(TECH.MATERIALS.SILICON_OXIDE, 1.0),

],

display_style=DisplayStyle(color=color.COLOR_YELLOW),

)

MSTACK_SOI_220nm_OX = i3.MaterialStack(

name="220nm Si + Oxide",

materials_heights=[

(TECH.MATERIALS.SILICON_OXIDE, 1.0),

(TECH.MATERIALS.SILICON, 0.220),

(TECH.MATERIALS.SILICON_OXIDE, 1.0),

],

display_style=DisplayStyle(color=color.COLOR_RED),

)

MSTACK_SOI_220nm_AIR = i3.MaterialStack(

name="220nm Si + Air",

materials_heights=[

(TECH.MATERIALS.SILICON_OXIDE, 1.0),

(TECH.MATERIALS.SILICON, 0.220),

(TECH.MATERIALS.AIR, 1.0),

],

display_style=DisplayStyle(color=color.COLOR_BLUE),

)

MSTACK_OX_AIR = i3.MaterialStack(

name="Oxide + Air",

materials_heights=[

(TECH.MATERIALS.SILICON_OXIDE, 1.0),

(TECH.MATERIALS.SILICON_OXIDE, 0.220),

(TECH.MATERIALS.AIR, 1.0),

],

display_style=DisplayStyle(color=color.COLOR_ORANGE),

)

# then compose a process flow

TECH.VFABRICATION.overwrite_allowed.append("PROCESS_FLOW")

PROCESS_FLOW = i3.VFabricationProcessFlow(

active_processes=[TECH.PROCESS.SI, TECH.PROCESS.OXIDE_OPEN],

process_layer_map={

TECH.PROCESS.SI: TECH.PPLAYER.SI,

TECH.PROCESS.OXIDE_OPEN: TECH.PPLAYER.OXO.TRENCH,

},

process_to_material_stack_map=[ # WG, OXIDE_OPEN

((0, 0), MSTACK_SOI_220nm_OX),

((0, 1), MSTACK_SOI_220nm_AIR),

((1, 0), MSTACK_SOI_OX),

((1, 1), MSTACK_OX_AIR),

],

)

Once the PROCESS_FLOW is defined, we can call visualize_2d, and see the updated virtual fabrication:

Rlayout.visualize_2d(process_flow=PROCESS_FLOW)

The default value of process_flow for visualize_2d is the PROCESS_FLOW defined in the technology.

We can persist it this way, so we can just call Rlayout.visualize_2d().

TECH.VFABRICATION.overwrite_allowed.append("PROCESS_FLOW")

TECH.VFABRICATION.PROCESS_FLOW = PROCESS_FLOW