Note

Go to the end to download the full example code

Running a CAMFR simulation to compute the field profiles

This sample illustrates how to setup a CAMFR simulation and compute the field distributions in your device.

The example starts from a layout defined for a custom TECHNOLOGY.

Note

A custom technology is not a requirement for the CAMFR simulator to work.

Illustrates

how to compute the wavelength and polarisation/mode dependent effective index

how to discretize a structure and define the CAMFR input

how to extract the simulated fields

Getting started

We start by importing camfr with other required modules:

import ipkiss3.all as i3

import numpy as np

import matplotlib.pyplot as plt

import camfr

The fabrication processes are specified in a TechnologyTree with a VFabricationProcessFlow.

For more details on defining a custom technology see also the

Technology guide.

from ipkiss.visualisation.display_style import DisplayStyle

from ipkiss.technology.technology import TechnologyTree

The Environment object is needed to specify the wavelength of interest.

from ipkiss.visualisation.color import Color

COLOR_LIGHT_BLUE = Color(name="Lightblue", red=0.78, green=0.84, blue=0.91)

COLOR_LIGHT_RED = Color(name="Lightred", red=0.9, green=0.4, blue=0.4)

COLOR_DARK_BLUE = Color(name="Darkblue", red=0.58, green=0.7, blue=0.91)

Defining the technology Materials and Virtual Fabrication

layer_wg = i3.Layer(0)

layer_rib = i3.Layer(1)

layer_clad = i3.Layer(2)

process_wg = i3.ProcessLayer(name="wg", extension="wg")

process_rib = i3.ProcessLayer(name="rib", extension="rib")

si = i3.Material(name="silicon", display_style=DisplayStyle(color=COLOR_LIGHT_RED), epsilon=3.45**2)

ox = i3.Material(name="oxide", display_style=DisplayStyle(color=COLOR_LIGHT_BLUE), epsilon=1.45**2)

mat_fact = i3.MaterialFactory()

mat_fact.si = si

mat_fact.ox = ox

i3.TECH.MATERIALS = mat_fact

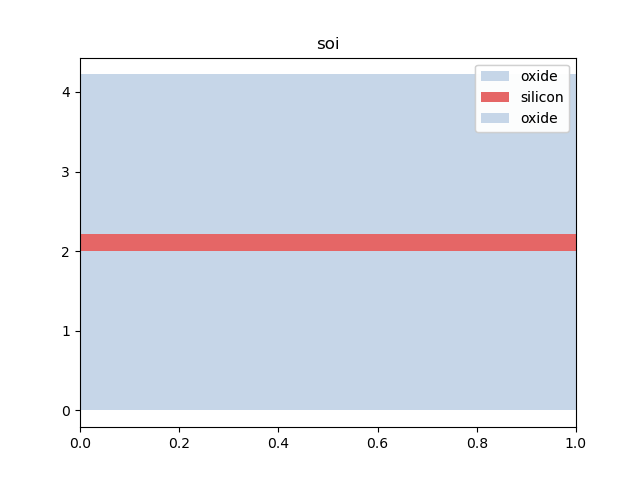

soi = i3.MaterialStack(

name="soi", materials_heights=[(ox, 2.0), (si, 0.22), (ox, 2.0)], display_style=DisplayStyle(color=COLOR_LIGHT_RED)

)

soi_etched = i3.MaterialStack(

name="soi_etched",

materials_heights=[(ox, 2.0), (si, 0.15), (ox, 0.07), (ox, 2.0)],

display_style=DisplayStyle(color=COLOR_DARK_BLUE),

)

allox = i3.MaterialStack(

name="all oxide",

materials_heights=[(ox, 2.0), (ox, 0.22), (ox, 2.0)],

display_style=DisplayStyle(color=COLOR_LIGHT_BLUE),

)

matstack_fact = i3.MaterialStackFactory()

matstack_fact.soi = soi

matstack_fact.soi_etched = soi_etched

matstack_fact.allox = allox

Mapping the material stacks

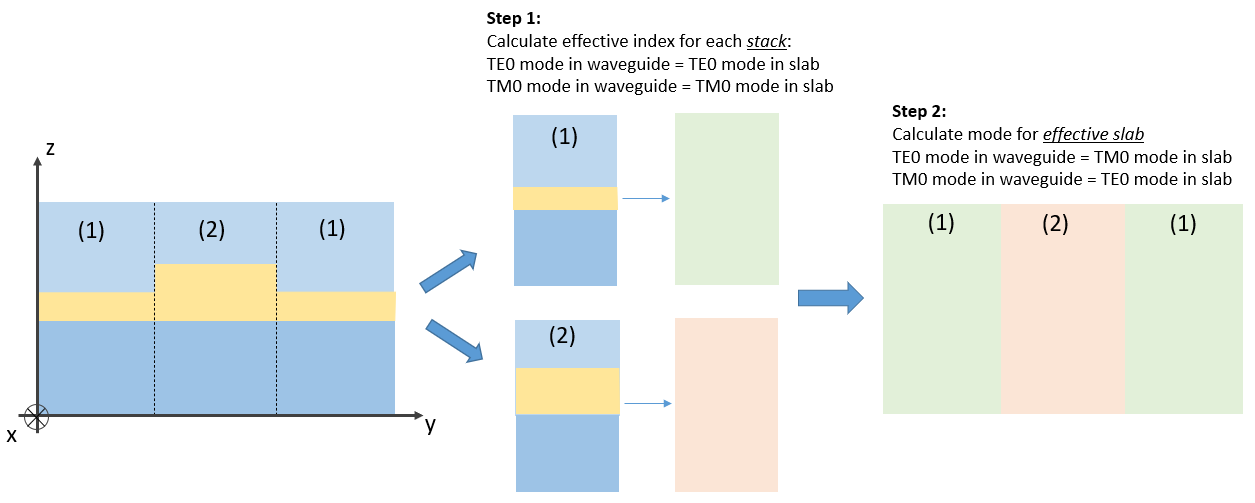

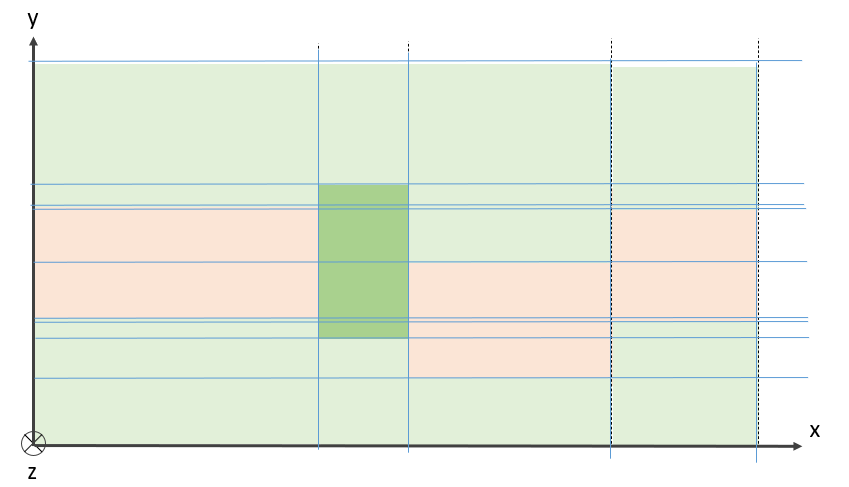

Converting a 2D cross-section of a waveguide into a 1D effective slab

For an arbitrary waveguide cross section we rely on the effective index approach to convert an essentially 2D problem into a 1D by defining an effective slab that is infinite along one direction. Each of the stack (labelled with 1 and 2 in Fig. Converting a 2D cross-section of a waveguide into a 1D effective slab) is converted to an effective material with the new (effective) index of refraction. Additionally, the modes are switched, so TE modes in the original structure become TM modes in CAMFR and the other way round.

To compute the effective indices we invoke

i3.device_sim.camfr_compute_stack_neff,

which requires an environment to account for the wavelength dispersion of our device and materials,

and the name of the mode.

This computation has to be performed for each MaterialStack.

Instead of providing purely a value for the effective index, we’re providing an effective Material, which leaves

an option of creating a model that can depend on environment parameters (for example, a wavelength dependence).

material_stack_to_material_map = dict()

wavelength = 1.55

environment = i3.Environment(wavelength=wavelength)

for _, ms in matstack_fact:

neff = i3.device_sim.camfr_compute_stack_neff(ms, environment=environment, mode="TE0")

material_stack_to_material_map[ms] = i3.Material(name="effective_" + ms.name, epsilon=neff.real**2)

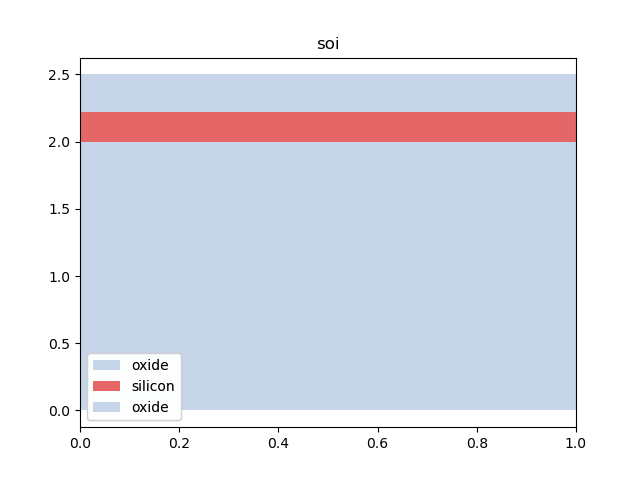

Furthermore, if we are not satisfied with the computed effective index, we can either limit the domain of the

computation by limiting (‘clipping’) our stack, or even overwrite the value.

Visual representation of a stack mstack.visualize() might help to choose the limits.

soi.visualize()

clipped_soi = soi.clip_copy(z_min=0, z_max=2.5)

clipped_soi.visualize()

neff = i3.device_sim.camfr_compute_stack_neff(clipped_soi, environment=environment, mode="TE0")

material_stack_to_material_map[soi] = i3.Material(name="effective_" + soi.name, epsilon=neff.real**2)

material_stack_to_material_map[allox] = i3.Material(name="effective_" + allox.name, epsilon=1.45**2)

Defining the layout

Next we define the layout of an MMI

vfab = i3.VFabricationProcessFlow(

active_processes=[process_wg, process_rib],

process_layer_map={process_wg: layer_wg, process_rib: layer_rib},

process_to_material_stack_map=[

((0, 0), allox),

((1, 0), soi),

((0, 1), soi_etched),

((1, 1), soi),

],

)

i3.TECH.VFABRICATION = TechnologyTree()

i3.TECH.VFABRICATION.PROCESS_FLOW = vfab

mmi = i3.LayoutCell(name="mmi").Layout(

elements=[

i3.Line(layer=layer_wg, begin_coord=(0.0, 0.0), end_coord=(10.0, 0.0), line_width=0.5),

i3.Line(layer=layer_wg, begin_coord=(10.0, 0.0), end_coord=(19.9, 0.0), line_width=2.9),

i3.Line(layer=layer_wg, begin_coord=(19.9, 0.5 + 0.25), end_coord=(29.9, 0.5 + 0.25), line_width=0.5),

i3.Line(layer=layer_wg, begin_coord=(19.9, -0.5 - 0.25), end_coord=(29.9, -0.5 - 0.25), line_width=0.5),

i3.Wedge(layer=layer_rib, begin_coord=(0.0, 0.0), end_coord=(5.0, 0.0), begin_width=0.5, end_width=1.2),

i3.Line(layer=layer_rib, begin_coord=(5.0, 0.0), end_coord=(24.9, 0.0), line_width=6.0),

i3.Wedge(

layer=layer_rib,

begin_coord=(24.9, 0.5 + 0.25),

end_coord=(29.9, 0.5 + 0.25),

begin_width=1.2,

end_width=0.5,

),

i3.Wedge(

layer=layer_rib,

begin_coord=(24.9, -0.5 - 0.25),

end_coord=(29.9, -0.5 - 0.25),

begin_width=1.2,

end_width=0.5,

),

i3.Line(layer=layer_clad, begin_coord=(0.0, 0.0), end_coord=(29.9, 0.0), line_width=6.0),

]

)

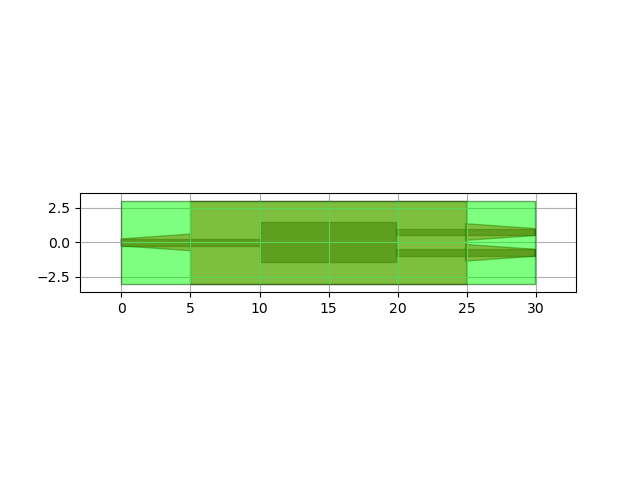

which can be visualized,

mmi.visualize()

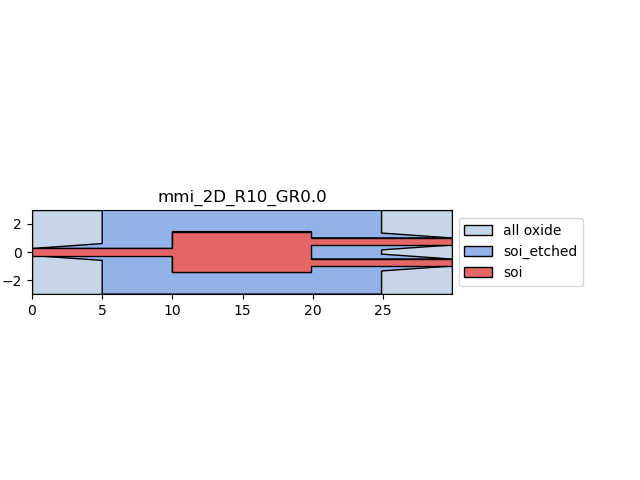

together with the virtually fabricated structure.

mmi.visualize_2d(process_flow=vfab)

Defining the CAMFR simulation

Setting the CAMFR parameters requires specifying the wavelength,

camfr.set_lambda(wavelength)

the number of modes,

camfr.set_N(20)

and the polarisation of the light. Notice that we specify camfr.TM polarisation because TM in the effective slab

is equivalent to TE in the original structure.

camfr.set_polarisation(camfr.TM)

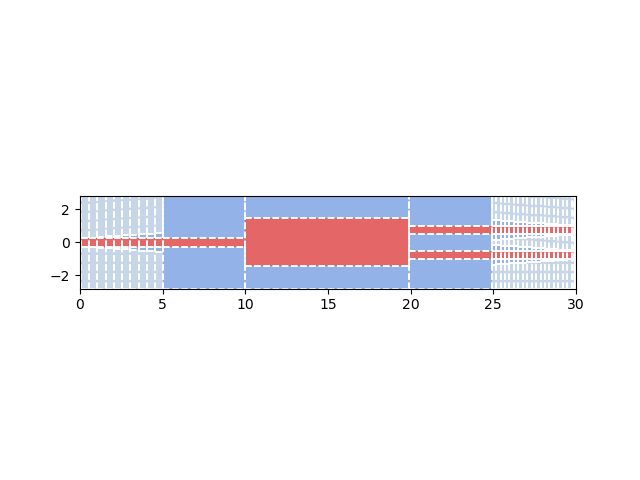

Before invoking the actual simulation we have to discretize our structure to provide an input

for the camfr.Stack(), which is a CAMFR object that defines the simulation.

We have already converted a 2D cross section to 1D by using the effective index method.

The discretization is performed to convert a longitudinally varying structure into a set of finite size (effective)

slabs,

Discretization of a longitudinally varying structure

as shown in Fig. Discretization of a longitudinally varying structure.

To do so we use the function

i3.device_sim.camfr_stack_expr_for_structure,

which requires the following parameters:

1 / discretisation_resolutiondefines what is the minimal change between the widths and lengths of consecutive needed for a new slab to be created.window_size_infois optional serves to limit the computational domain.process_flowandmaterial_stack_factoryare also optional and serve to define a custom virtual fabrication.

More importantly, we need to provide the material_stack_to_material_map for every MaterialStack

from the TECHNOLOGY that we use.

Finally, we can also visualize the discretized structure to be more confident that the discretization

is done as requested.

window_si = i3.SizeInfo(west=0.0, east=30.0, south=-2.8, north=2.8)

stack_expr = i3.device_sim.camfr_stack_expr_for_structure(

structure=mmi,

discretisation_resolution=30,

window_size_info=window_si,

process_flow=vfab,

material_stack_factory=matstack_fact,

environment=environment,

material_stack_to_material_map=material_stack_to_material_map,

visualize=True,

)

Running the CAMFR simulations

Once the structure is discretized and the parameters are set, we can define a camfr.Stack

from the set of (effective) slabs that we previously obtained.

camfr_stack = camfr.Stack(stack_expr)

Further, we want to define a input mode at our structure. For example the fundamental mode of our system.

To invoke the simulation simply run,

camfr_stack.calc()

from where we can obtain the the input and the output field profiles.

slab_start = camfr_stack.inc()

slab_end = camfr_stack.ext()

Visualizing the simulation data

Note

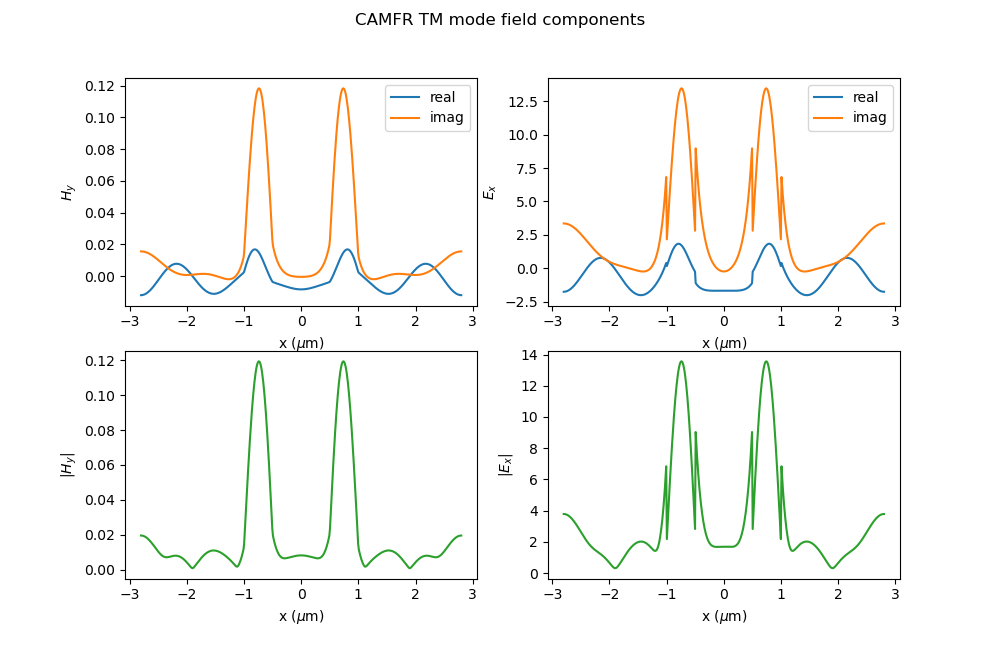

CAMFR uses a different coordinate system compared to Ipkiss (Ipkiss x, y, z -> CAMFR z, 1, 2). The latter is being used in the following figure.

num_points = 501

x_positions = np.linspace(0, window_si.height, num_points)

OH2 = np.zeros(len(x_positions), dtype=complex)

OE1 = np.zeros(len(x_positions), dtype=complex)

for x_pos, i in zip(x_positions, range(len(x_positions))):

coord_output = camfr.Coord(x_pos, 0.0, window_si.width)

field_output = camfr_stack.field(coord_output)

OH2[i] = field_output.H2()

OE1[i] = field_output.E1()

shifted_x_position = x_positions + window_si.south

fig = plt.figure(figsize=(10, 6.5))

fig.suptitle("CAMFR TM mode field components")

plt.subplot(221)

plt.plot(shifted_x_position, OH2.real, "C0", label="real")

plt.plot(shifted_x_position, OH2.imag, "C1", label="imag")

plt.ylabel(r"$H_y$")

plt.xlabel(r"x ($\mu$m)")

plt.legend()

plt.subplot(222)

plt.plot(shifted_x_position, OE1.real, "C0", label="real")

plt.plot(shifted_x_position, OE1.imag, "C1", label="imag")

plt.ylabel(r"$E_x$")

plt.xlabel(r"x ($\mu$m)")

plt.legend()

plt.subplot(223)

plt.plot(shifted_x_position, abs(OH2), "C2", label="abs")

plt.ylabel(r"$|H_y|$")

plt.xlabel(r"x ($\mu$m)")

plt.subplot(224)

plt.plot(shifted_x_position, abs(OE1), "C2", label="abs")

plt.ylabel(r"$|E_x|$")

plt.xlabel(r"x ($\mu$m)")

plt.show()